|

GAS ENGINES, INTERNAL COMBUSTION FOR ELECTRICITY GENERATION

|

||

|

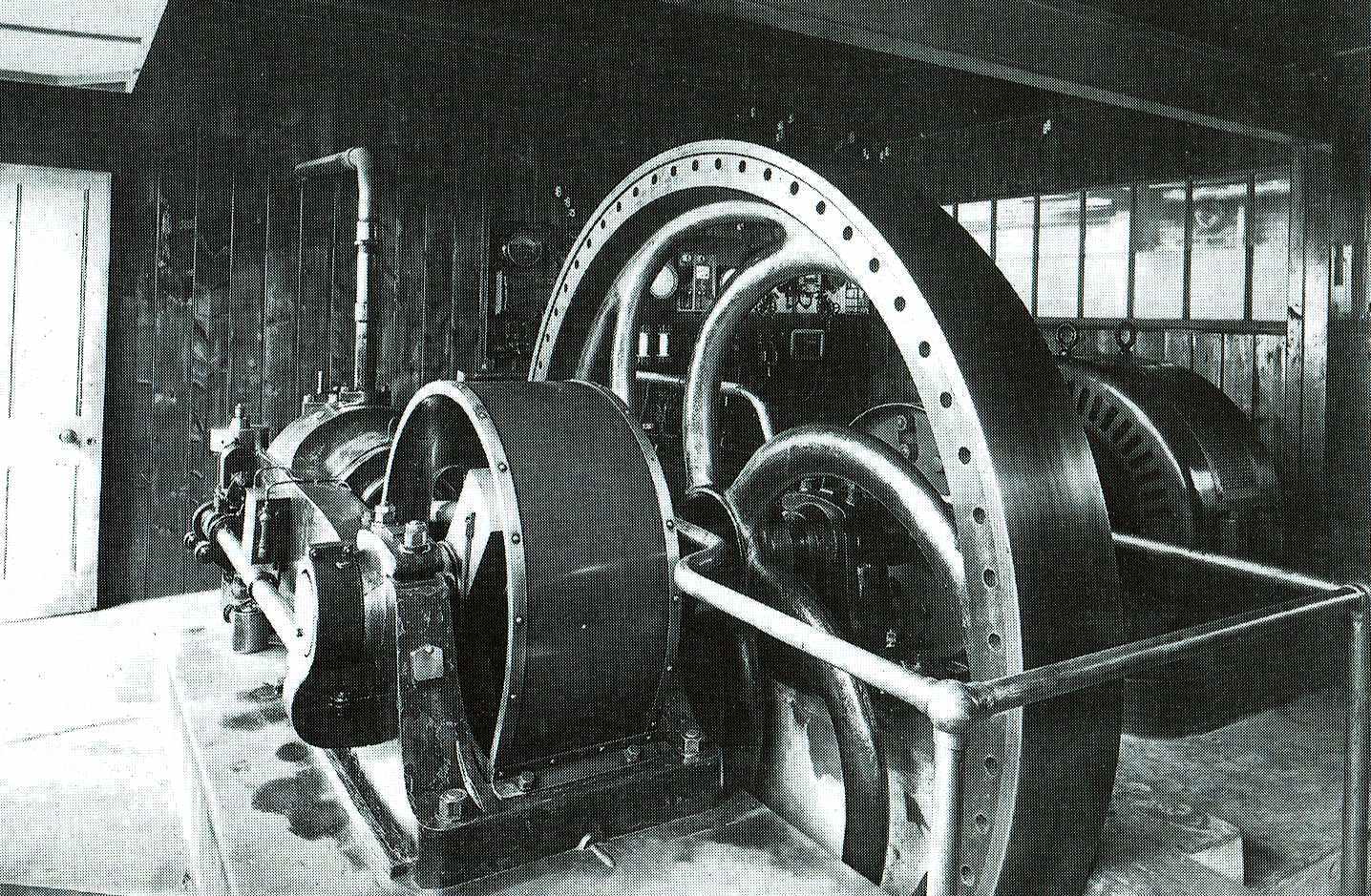

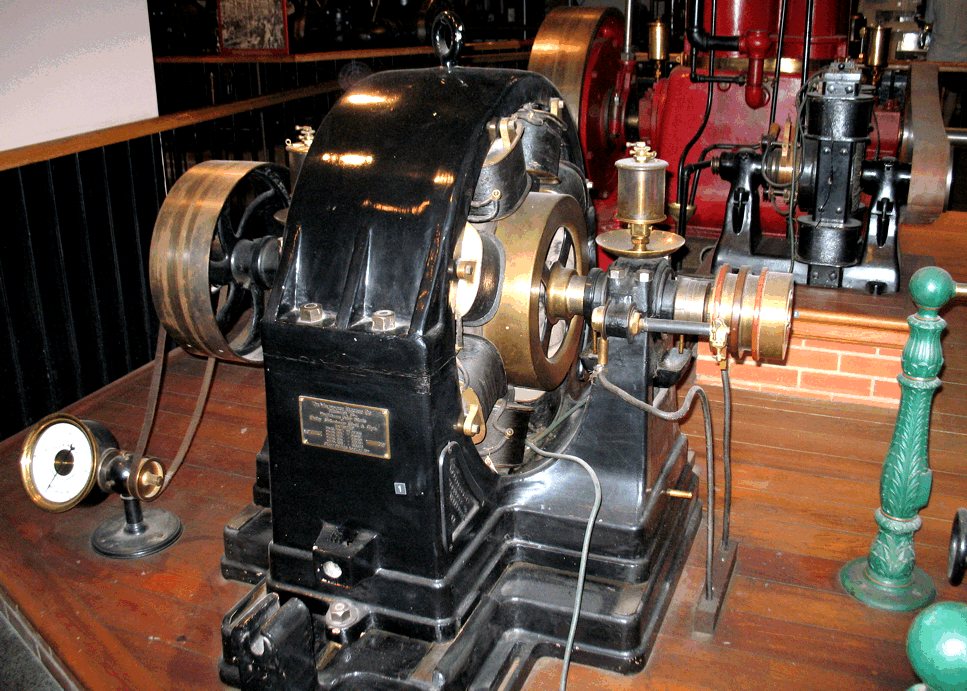

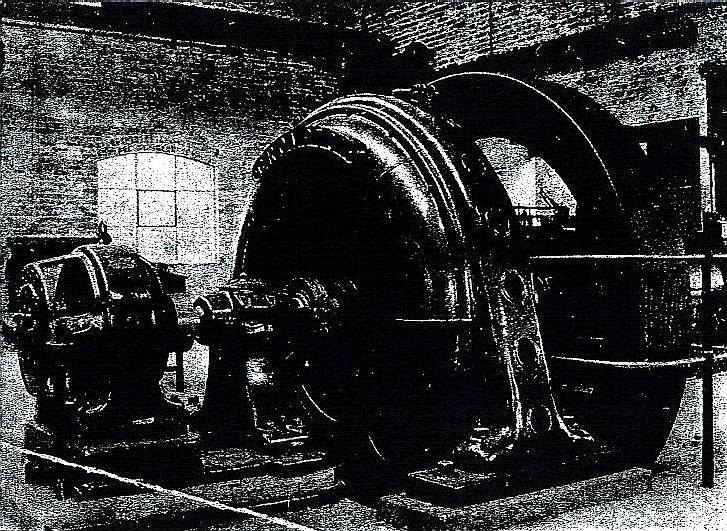

GAS ENGINE - Mounted on substantial concrete bases and secured by large steel bolts, this is a picture of a generator that did the rounds in Sussex, finally ending up powering a tram in Eastbourne in the 1960s, but not before being used to drive machinery for the Eastbourne Aviation Company between 1911 and 1924. This generator set is virtually identical to the one that was situated in Herstmonceux Museum around 1909, identified by the concrete base footprint. The pine match-boarding and electrical controls are also near identical in layout. This was because the electrical engineer who carried out the work was the same man: Charles William de Roemer.

For Charles, this generating room must have felt just like the one he'd installed where he lived at Lime Park, just on the outskirts of Herstmonceux village. The flywheel of the engine looks like a Crossley design but we are reliably informed that it is a National engine. We think though that the first dynamo on this site was an Edison-Hopkinson machine that may have been belt driven, after John Hopkinson and Thomas Edison. That said, the generator attached to the engine seen above is a Crompton dc machine of 110/220 votls. Charles de Roemer and/or the Baron Karl von Roemer, is known to have had an association with John Hopkinson and possibly his brother Charles Hopkinson. There are two large concrete bases at Herstmonceux Museum with flywheel troughs, meaning that there must have been two generating sets. The two bases are quite different in configuration and in different parts of the building complex.

INDUSTRIAL LAYOUT - This CAD drawing shows the layout of the generating installation in plan view. You can see how the whole unit was geared to generating and storing electricity in fairly large quantities. A 36 horsepower generator working at 75% overall efficiency (engine & generator losses) would produce 26.85 kilowatts of energy. If the engine was run from nine o'clock in the morning until five o'clock in the afternoon it would make 214.85kW of electricity. At £0.172 pence per unit today that would be worth £37 pounds a day. Charles de Roemer charged 1.5 old pennies per unit, so made £13.43 pounds a day, minus fuel, battery depreciation and labour costs. In those days you could buy a house for a few hundred pounds meaning that the enterprise was in theory quite profitable.

Today you could store 215kW in one Tesla truck battery. In 1909 you would need a whole room full of wet lead-acid batteries - and that is exactly what Charles had in situ according to Ronald Saunders, whose dad was one of the engineers who worked in Lime Park.

Literally hundreds of gas engines survive to this day, while the old buildings that house them are gone. Why? Because of the pressure for development and land prices. This is the unfortunate part of man's development. The good news is that there are many engineering enthusiasts who are willing to give their time to preserving and restoring the gas engines that propelled mankind into the age of electricity.

Herstmonceux Museum is unique in all the world, in that it survives while the engines are gone, in some kind of strange reversal of property development norms. For this reason it is all the more important that as much of the original building is treated to survive, while at the same time generating some kind of beneficial use to help pay for the upkeep of such a rare wooden building. On this front we are considering using Virtual Reality technology to digitally re-create what is missing for industrial archaeology enthusiasts. We would then have a virtual gas engine on permanent display in the premises and on the internet, such that millions of people around the world could visit this part of Sussex in the year 1909.

WHAT IS A GAS ENGINE?

A gas engine is an

internal combustion engine which runs on a gas fuel, such as

coal gas, producer gas, biogas, landfill gas or natural gas. In the UK, the term is unambiguous. In the US, due to the widespread use of "gas" as an abbreviation for gasoline, such an engine might also be called a gaseous-fueled engine or natural gas engine or spark ignited.

Externally, one could be forgiven for confusing steam engines, with diesel or gas engines - because they were all large machines, with large open flywheels and mostly horizontal cylinders. Of course this changed as vertical engines came to dominate the market.

There are several concrete mounts at Herstmonceux Museum. Leading us to believe that there may have been a steam engine at one point in time, or maybe a diesel engine. This is in addition to the two mounts that have deep flywheel troughs. The only way to be sure would be for an expert with a good reference archive, to measure the mounts to match them up with the appropriate engine. Fortunately, we do have CAD drawings of the installation that were produced from accurate measurements taken in 1998, before the ground works were covered over to protect them.

Where other gas engines are mounted on raised brick or concrete plinths, the mountings at Herstmonceux are set into the ground, with the flywheel running below ground level in a semi-circular concrete trough. The remaining floor area is covered with large concrete (sharp sand) slabs.

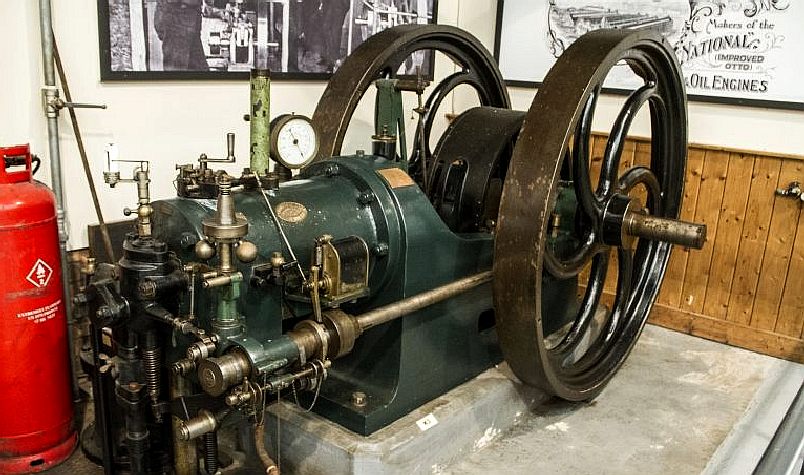

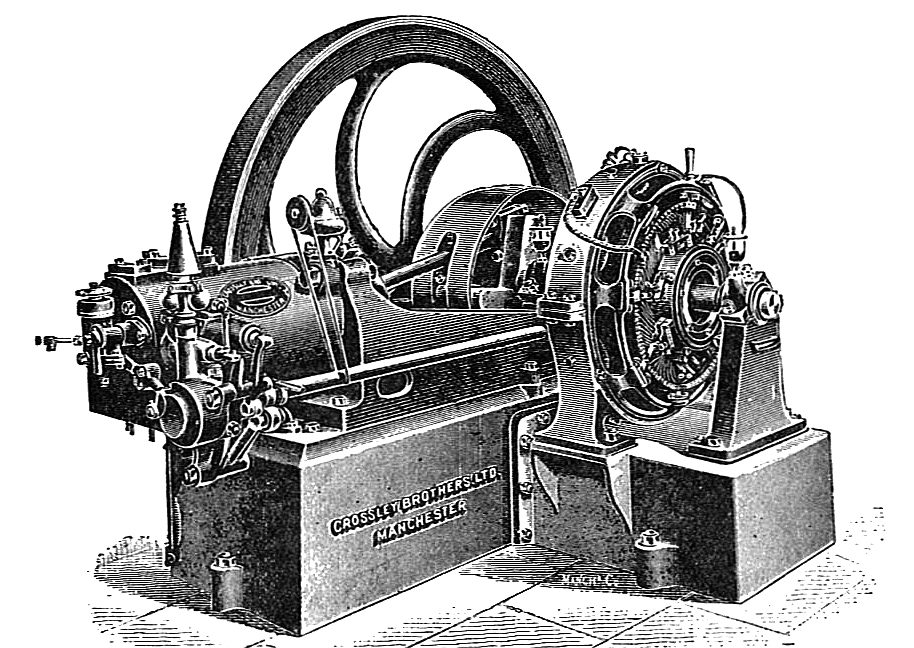

CROSSLEY BROTHERS - This is a fine example of one of the single cylinder Crossley gas engines, featuring sturdy castings, mounted on a tiled plinth.

GAS ENGINE HISTORY

LENOIR

OTTO

and LANGEN

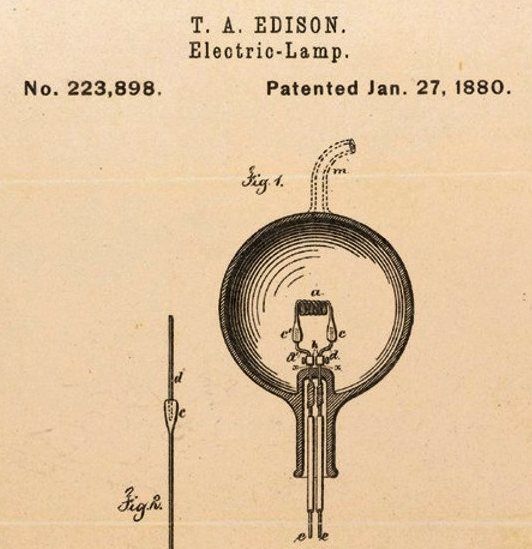

SEE THE LIGHT - The incentive to generate electricity was driven by the desire to replace gas lighting with something safer and more convenient. Gas lighting replaced candles in the evolution of domestic lighting, but still required the gas to be lit manually. This was a great improvement on candles, but imagine seeing a light bulb for the first time. No messy matches and no risk of explosions. It's a bit like comparing incandescent bulbs to LEDs. Modern lighting using light emitting diodes is up to 10 times more efficient than some of the best filament bulbs. Almost all the lighting at Herstmonceux Museum is now LED, even the external security lamps.

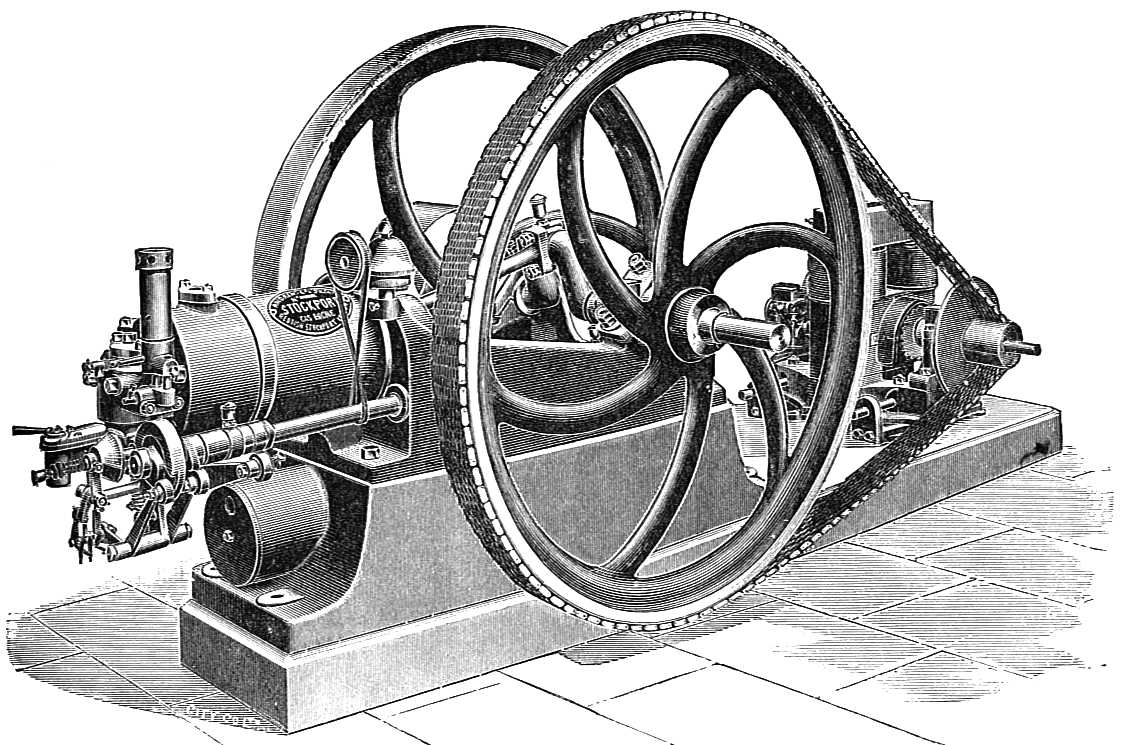

BELT DRIVE - We found part of a belt drive pulley from a generating set on site at Herstmonceux Museum, very much like the one seen on the left of this unidentified machine. This find tends to support the theory that the second generating mount was used to drive a generator like the one above via a belt.

FOUR STROKE ENGINE

CROSSLEY

TANGYE - This is a steam engine from Tangye, a company that also manufactured gas engines. Once again, the general configuration is near identical to a gas or steam engine, to the untrained eye.

TANGYE

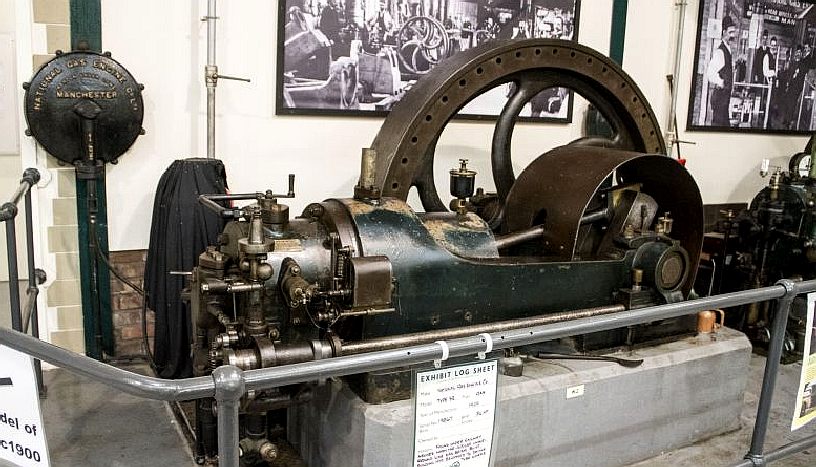

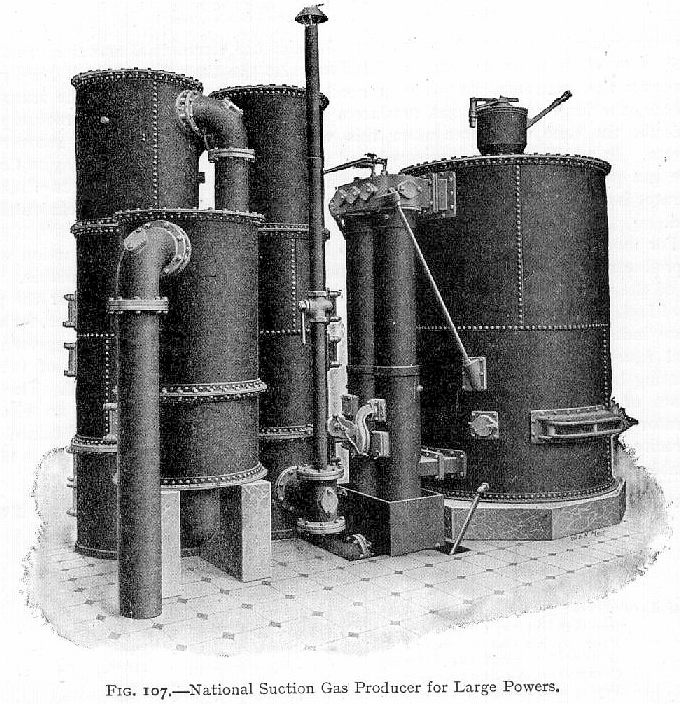

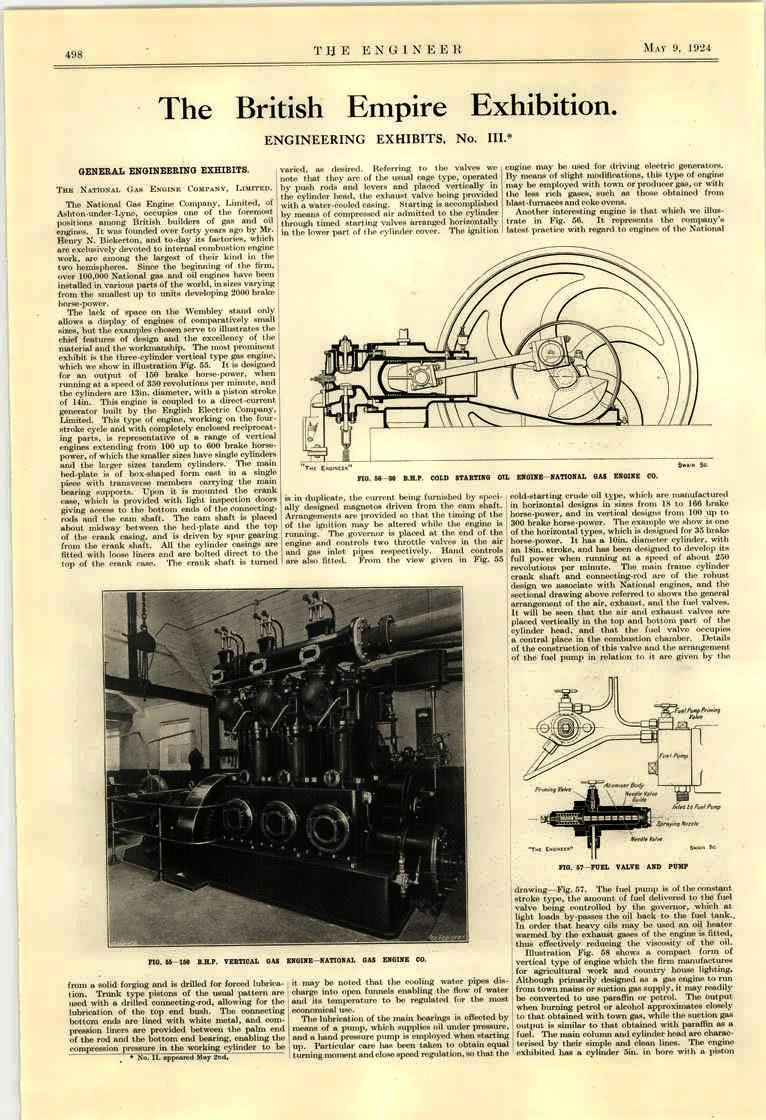

ANSON MUSEUM - This is a photograph of a National gas engine that was made close to the Anson Museum at Ashton Under Lyne.

NATIONAL GAS ENGINE HISTORY

By 1908, the demand for small horizontal gas engines was diminishing rapidly,

ironically, due to competition from the electric motor and in that year, work was commenced on building a new block of bays at the west end of the works for the manufacture of vertical tandem gas engines up to units of 2,000

b.h.p. with 12 cylinders having a bore and stroke of 26in x 24in. Many installations of 10,000

b.h.p. or more were laid down at collieries, iron and steel works etc., for running on blast furnace and coke oven gases. This new section of the works was equipped with special machines for carrying out this operation.

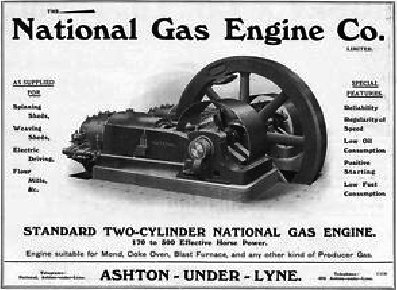

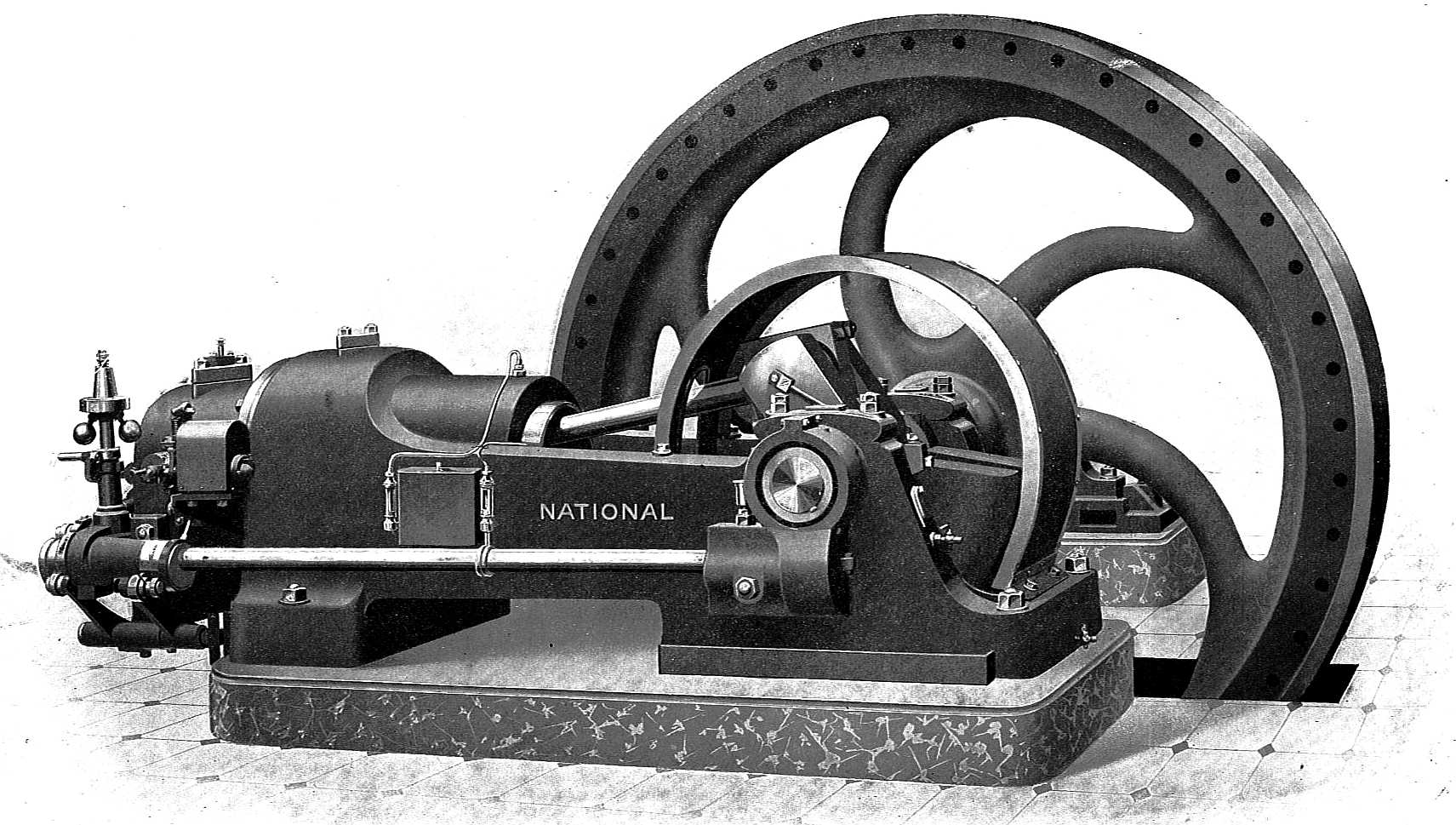

NATIONAL - This is a drawing of a 36hp ordinary gas engine from 1905. The engines were designed originally to run on town gas and a later development was the gas producer plant using anthracite, coke and waste fuels such as wood, cotton seed etc. The introduction of the gas plant increased enormously the demand for gas engines, as they not only proved to be the most economical power available at the time but combined engines and gas plants could be installed anywhere in the world where solid fuel was available from which the gas could be extracted. In the early part of the century, many hundreds of gas producer plants and engines were shipped to all parts of the world. In the year 1906, a new type National gas producer was exhibited at the Royal Agricultural Show, Derby, and was awarded the gold medal.

With the advent of the compression ignition engine the National Compnay developed this branch of the business. Previously , oil engines had been confined to the hot-bulb or hot-spot type and they now embarked on the compression ignition types, beginning with horizontal engines. Very quickly, a large order book was built up for these units. Concurrently, the vertical engine department developed vertical engines with up to 17in diameter cylinders by 21 in stroke. These were subsequently extended to give outputs up to 2,000

b.h.p. utilising turbo-pressure-chargers.

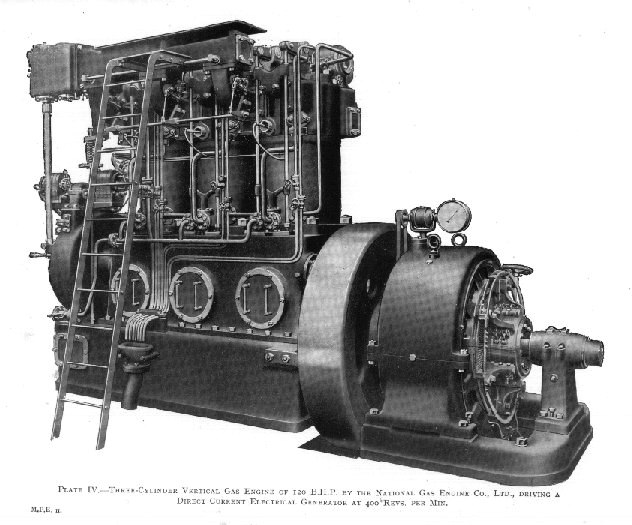

NATIONAL - This is a picture of a vertical three cylinder gas engine that produced 120 bhp at 400 rpm driving an inline DC generator.

During the 1939-1945 war, the National Company supplied vast numbers of engines to Government requirements. In addition, contracts were undertaken for the manufacture of jigs for the Manchester and Lancaster bombers, hydraulic recuperators for 25 pounder guns, and groups of machines were laid down for the manufacture of blade adaptors for the Rotol variable pitch propellor and also for machining propellor hubs.

CROSSLEY - This is a drawing of another single cylinder Crossley gas engine, featuring a dynamo that is directly driven from the crankshaft.

STOCKPORT - Single cylinder gas engine with twin flywheels, where a belt is used to drive a dynamo.

TECHNICAL

Gas engines that run on natural gas typically have a thermal efficiency between 35-45% (LCV

basis). The best engines can achieve a thermal efficiency of slightly more than 48% (LCV basis). These gas engines are usually medium speed engines Bergen Engines Fuel energy arises at the output shaft, the remainder appears as waste heat. Large engines are more efficient than small engines. Gas engines running on biogas typically have a slightly lower efficiency (~1-2%) and syngas reduces the efficiency further still. GE Jenbacher's recent J624 engine is the world's first 24-cylinder gas engine with high efficiency running on

methane.

PYROLYSIS CHAMBER - This steel cylinder was unearthed in the summer of 2016. Unfortunately, it had been flattened and was badly corroded, but the timber mounts that were in turn set in cement on a concrete base, were reasonably well preserved. We also found the unique concrete mounts for this cylinder, that were cast in segments. You can see the segmented base in the right hand picture below, under the cylinder on the far right.

COAL ON SITE - When excavating on an important historic site like this, you must document all of the finds, no matter how seemingly irrelevant. You won't be surprised to learn that we found a large amount of high quality coal under the grass/soil surface when digging about.

SEEBOARD MAGAZINE - The October edition of 1970 contains some useful information about where, how and who was responsible for laying electricity mains cables in the Weald area of East Sussex, including mention of Rudyard Kipling and Batemans. R. F. Couchman, the former District Engineer is not quite right about the generating facilities, but appears to be confirming that the second generator mount, the smaller one in the north-eastern range, was an oil engine. Indeed there were two generating mounts, one very large with piping for a gas supply and all the associated bits and bobs, while the other had a smaller flywheel trough and was belt, rather than direct shaft drive. Mr Couchman ignores the fact that there were two engine mountings, separated by dividing (or partition) walls between the building ranges. The Crompton 250kVA generator above was powered by a town gas engines. It was a single phase set operating at 240 volts. These were the pioneering days of electricity generation in the Weald and Tunbridge Wells districts.

COAL GAS

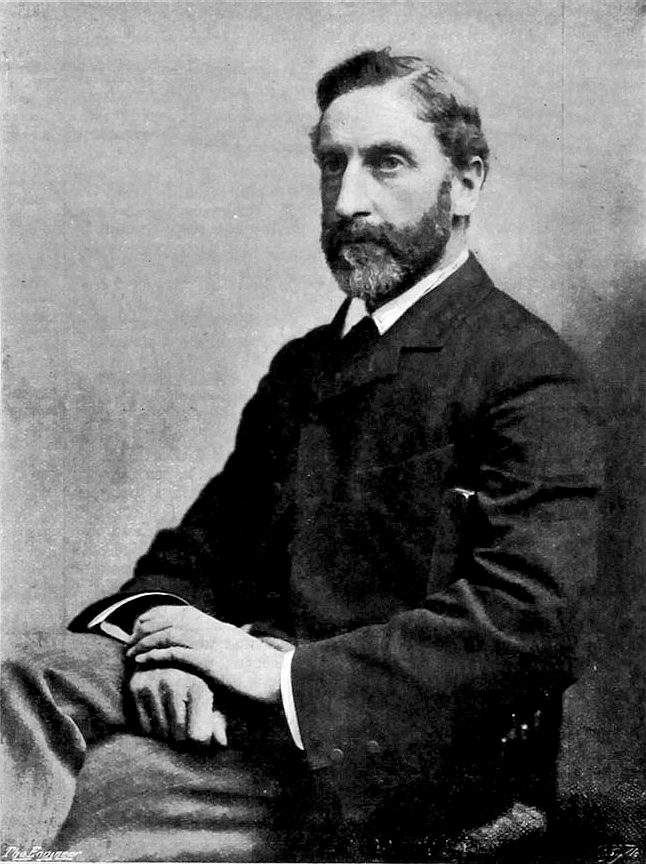

DR. JOHN

HOPKINSON - was the eldest son of Alderman John Hopkinson, formerly Mayor of Manchester,

he was born in that city on 27th July 1849. His school days were spent at Lindow Grove School near Manchester, and Queenwood College, Hampshire.

Because of his work on electric lighting, batteries and generating, and his association with the Edison lighting company, later Edison-Swan, Dr Hopkinson is thought to have known and worked with Charles de Roemer as well as Thomas Edison.

DESTRUCTIVE DISTILLATION

ANSON ENGINE MUSEUM

Anson Engine Museum Tel:

01625 874 426

DONATIONS

GAS ENGINE MAGAZINE

FLAME

IGNITION - A Historical Account of Flame Ignition in the Internal

Combustion Engine by Wayne S. Grenning. Flame IgnitionThis book is a

scholarly work describing flame ignition as applied to reciprocating

engines, from early experiments to later successes such as the Deutz and

Crossley versions of the four stroke cycle perfected by Otto in 1876.

Wayne discusses problems encountered by the early entrants into the gas

engine industry, highlighting solutions discovered by the various players. He also goes into more arcane subjects like the constant pressure cycle introduced by Brayton that survives today in the gas turbine engine, to a look at toy non-compression engines produced during the same early days as their full size brethren. In eight chapters, Wayne shows details of engines built by Clerk,

Sombart, Forest and others, gives technical details on the construction and operating features unique to flame ignition engines, and highlights the struggles other manufacturers endured to avoid infringing the Otto patents. The section on the four-stroke-cycle engines is by itself over 300 pages long, covering 30 different companies. It has 67 pages describing the activities of Crossley Brothers in Manchester, England and another 53 pages dedicated to Gasmotoren Fabrik Deutz from Cologne, Germany.

COOLSPRING POWER MUSEUM

Coolspring Power Museum presents an illuminating history of the evolution of internal combustion engine technology that put an end to the steam powered era. The museum's collection includes over 275 stationary engines housed in more than 20 display buildings.

179 Coolspring Rd

ABOUT COOLSPRING

RUSTON - This is not a gas engine, it is powered by oil, but the general configuration is such that the casual observer might think it is steam or gas powered. In the case of the generating buildings at Herstmonceux, the gas producing plant was often confused with steam production - especially as coal was in the frame, and is usually associated with locomotive steam engines and water boilers.

LINKS & REFERENCE

http://www.enginemuseum.org/ http://www.facebook.com/pages/Anson-Engine-Museum/92461372208?ref=hl http://www.gasenginemagazine.com/ http://www.coolspringpowermuseum.org/ http://www.gracesguide.co.uk/National_Gas_Engine_Co http://www.gracesguide.co.uk/National_Gas_Engine_Co Wikipedia_Destructive_distillation Graces

guide UK Charles_Hopkinson_1854 - 1920 Graces guide UK Edison_and_Swan_United_Electric_Light_Co Antique Engines by the Davis Family Featuring Detroit Engine Works Antique Small Engine Collectors Club ASAP Motors - Machines of the Past Ashtabula County Antique Engine Club American Society of Mechanical Engineers Blue Fuel White Smoke Stationary Engine Collection Brookville Chamber of Commerce Canadian Museum of Making: Forging, Machining, & Derivative Artifacts Connecticut Antique Machinery Association Drake Well Museum - Birthplace of the Oil Industry - 1859 Historical Construction Equipment Association Jacktown-Blue Mountain Antique Gas & Steam Engine Association Maryland Steam Historical Society Miniature Engineering Craftsmanship Museum - Find Hansen Collection Miniature Engineering Craftsmanship Museum - Paul Knapp Collection Miniature Engineering Craftsmanship Museum - George Luhrs Collection Pennsylvania Federation of Museums and Historical Organizations Pennsylvania Historical and Museum Commission Peter & Rita Forbes' Engine Webpages Pioneer Valley Military Transportation Museum Punxsutawney Chamber of Commerce Rough and Tumble Engineers Historical Association Western Minnesota Steam Threshers Reunion Western Pennsylvania Museum Council https://en.wikipedia.org/wiki/Destructive_distillation https://en.wikipedia.org/wiki/Gas_engine http://www.gracesguide.co.uk/Charles_Hopkinson_(1854-1920) http://www.gracesguide.co.uk/Edison_and_Swan_United_Electric_Light_Co

COAL BANK - You cannot see the coal bunkers in this picture because they are built into the bank. One range of the extant buildings was removed in 1936 to allow the transport of the largest gas engine. It was the intention of Charles de Roemer to put the unit back but then fate intervened and the Weald Supply Company came along to spike his guns. Just as Charles was about to repair the section to the rear, along came World War Two, when he temporarily clad the remaining units in corrugated iron to make a hospital for wounded airmen. Lime Park Heritage Trust are looking at ways getting the archaeology more intact so that visitors to the site can see what it looked like in 1909 - or get a better impression of the full size of the installation.

BUNKER REPAIRS - The front wall of this coal bunker had been pushed over by rogue sycamore trees. We used the original bricks wherever possible, cleaned and jet washed. This face was rendered and will be again given sufficient funds for restoration. The rubble had become overgrown with grass and the empty bunkers a dumping ground for hardcore that is now being usefully employed as the underpinning for a concrete lid to help preserve the feature for generations to come. This picture is Copyright © Lime Park Heritage Trust December 2016. You will need the permission of the Trust to reproduce this picture except for private study or educational use by teachers for their students.

WWII AIR RAID SHELTER - This World War Two bomb proof air raid shelter is built in line with the coal bunker that it was derived from, being divided up into sections internally. It is reasonable to assume that before 1936 this brick built range was all one coal storage facility because what is now the air raid shelter is directly opposite the gas conversion heater. In days gone by the courtyard is most likely to have been a hall or covered way. This picture is Copyright © Lime Park Heritage Trust 18 December 2016. You will need the permission of the Trust to reproduce this picture except for private study or educational use by teachers for their students.

HERITAGE INDEX A - Z

AVIATION - EASTBOURNE BARCLAYS BANKING LET DOWN - MISSING ACCOUNT MONEY BARON CARL VON ROEMER & CHARLES de ROEMER CAMPBELL HALL - BLUEBIRD ELECTRIC CARS GAS ENGINES - COAL CONVERSION, INTERNAL COMBUSTION OBSERVATORY - HERSTMONCEUX CASTLE SOLAR LADY - STATUE

GOOGLE MAPS - The detail is not that great and the situation on the land is significantly changed in that the site has undergone a massive clean up. You cannot see the coal bunkers in this picture, but they are to the rear of the main buildings.

|

||

|

This website is Copyright © 2017. All rights reserved. All other trademarks are hereby acknowledged. Contact Us www.cherrymortgages.com

|